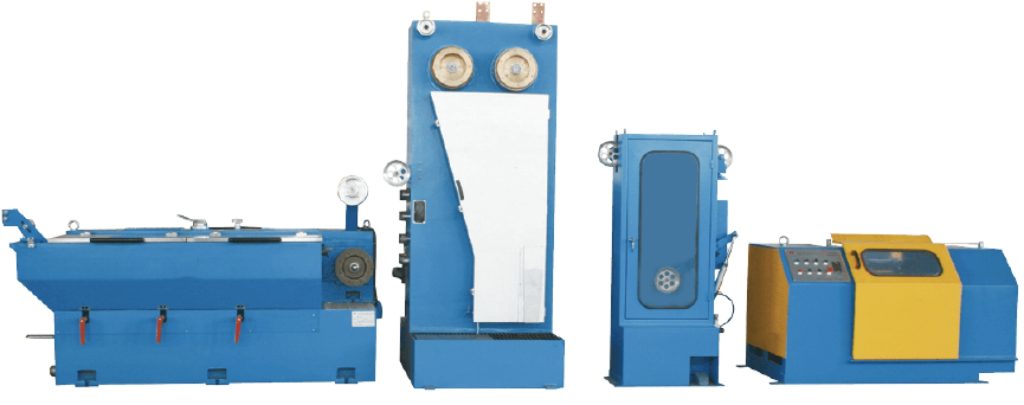

The intermediate copper wire drawing machine has been carefully engineered for drawing copper wires from a maximum diameter of 3.5mm into wires possessing a minimum diameter of up to 0.4mm.

| Machine Type | M280/13DH | M300/9DH | M250/13DH | M250/17DH | M260/17D-C | M260/17D |

| Max. Inlet Dia.(mm) | Ф 3.5 | |||||

| Outlet Dia. ( mm ) | Ф 0.65~ Ф 2.8 | Ф 1.2~ Ф 2.8 | Ф 0.65~ Ф 1.60 | Ф 0.4~ Ф 1.6 | Ф 0.4~ Ф 1.5 | Ф 0.4~ Ф 1.2 |

| Max. Die No. | 13 | 9 | 13 | 17 | 17 | 17 |

| Max. Line speed (M/Min ) | 2000 | 1200 | 1800 | 1800 | 1500 | 1200 |

| Body structure | Ironed cast | |||||

| Slip Ratio of Machine | 20% | 18% | 20% | 20% | 18% | 18% |

| Fix Speed Capstan Dia.(mm) | 280 | 300 | 250 | 250 | 260 | |

| Transmission Type | By high precision grinding gear | By Chain | ||||

| Main Motor Power (KW) | 55 (45) | 37 | ||||

| Take-Up Motor Power (KW) | 11 (15) | 11 | ||||

| Lubrication Type | Full Immersion | Spray type | ||||

| Take-Up Bobbin Size (mm) | Φ 500/ Φ 630 ( Bore is Φ 127mm) or changed by requirement | |||||

| Optional Equipment | 1. Continuous annealing device | |||||

| 2. Coiler | ||||||

| On-Line Continuous Annealing Device | ||||||

| Type | 350T | 250T/B | 250T/A | |||

| Machine Structure | horizontal | vertical | vertical | |||

| Annealing Wheel Dia. (mm) | Ф 350 | Ф 250 | Ф 250 | |||

| Annealing Wire Dia. (mm) | Ф 0.8~ Ф 2.8 | Ф 0.6~ Ф 2.2 | Ф 0.4~ Ф 1.2 (Ф 0.4~ Ф 1.6 ) | |||

| Annealing Protection Type | steam or nitrogen | |||||

| Annealing Voltage (DC) | 0~65V | 0~60V | ||||

| Annealing Current (DC) | 0~2500A | 0~(2000A . 1500A . 1200A) | ||||

Finished products by Intermediate Wire Drawing Machine With Annealer can be: